Condition Based Monitoring is a proactive maintenance health check for all types of electromechanical equipment and is crucial for identifying underlying system performance issues without the need to stop production. Avonmouth Engineering Services Ltd, who are experts in this field, were happy to provide the service recently to the UK’s leading aerospace company, Leonardo, to investigate a loud noise being generated by a lathe gearbox.

Condition Based Monitoring is a proactive maintenance health check for all types of electromechanical equipment and is crucial for identifying underlying system performance issues without the need to stop production. Avonmouth Engineering Services Ltd, who are experts in this field, were happy to provide the service recently to the UK’s leading aerospace company, Leonardo, to investigate a loud noise being generated by a lathe gearbox.

The lathe is a critical item of plant at Leonardo as it is the first step in the gear machining process. The cost to purchase a new machine would have far exceeded £100,000 and led to a loss of production.

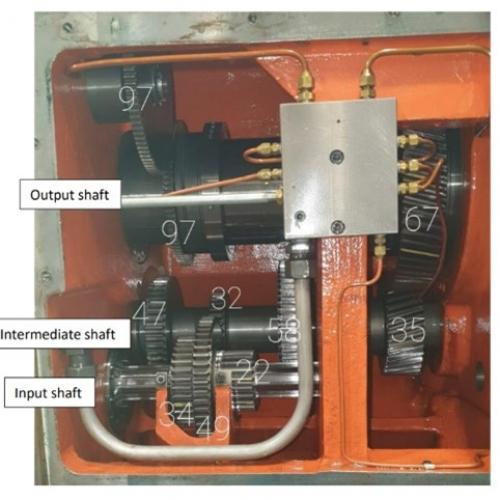

Avonmouth Engineering Services, who have an integrated service partnership with Leonardo, carried out detailed vibration analysis on the equipment. Vibration analysis is a non-intrusive method which can be used to detect obscure faults such as unbalance, resonance, misalignment or bearing failure. Combining the results with the technical drawings - which outlined the number, location and specification of the gears and bearings in the gearbox - Avonmouth Engineering Services were able to pinpoint that the exact cause of the excessive vibration was down to one single bearing. Leonardo carried out the bearing change and have confirmed that the machine runs perfectly.

Leonardo was delighted that the problem could be so easily identified and rectified and that the critical piece of machinery is back to optimum performance. Condition Based Monitoring opens up a world of possibilities and opportunity for any business to monitor, diagnose and fully understand how a machine, or elements thereof, are performing in its operational environment. Without the need to cease function or production it is vital to Leonardo’s planned maintenance programme with Avonmouth Engineering Services, which includes monthly CBM assessments, annual motor health checks and the service and calibration of manufacturing plant and equipment to minimise downtime and keep the production line moving.